Tennant20: Osmium Coating System

Discovery awaits beneath an ultra-thin veil

“Neoc-Pro” is now “Tennant20”

Meiwafosis Co., Ltd. developed original discharging electrodes and released “Multifunction Coater” with sputter coating, plasma CVD and hydrophilic treatment features in 1997. We continuously improved the system for over 20 years and developed “Neoc Osmium Coater -Neoc Series-” with a much larger negative glow charge phase by special electrodes.

The deposition quality is superior to the sputter coater. The Neoc Series have been used in various research fields such as SEM observation and elemental analysis since its release.

In 2021, we successfully created the advanced osmium coating system “Tennant20.” The new system reflects our firm belief that our products should be user-friendly and safe. Keeping the original features and functions, the system has additional advantages.

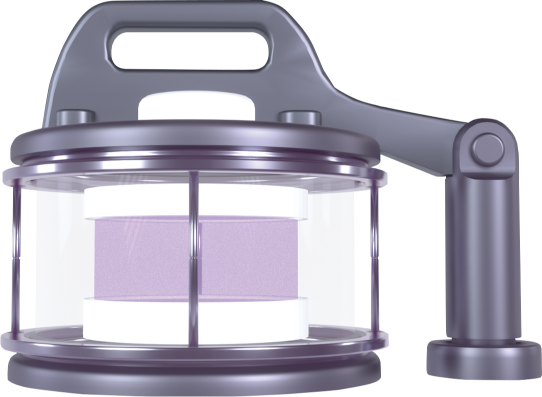

User-friendly design

The handle shape is suitable for opening/closing the lid, the angle of the screen is optimized for better digital communication, and the body is adjusted to smooth ampule handling. All details ensure easy operation and maintenance.

(Product Designer Atsushi ONUMA)

Story behind Tennant20

The “Tennant20” is derived from the name of an English chemist, Smithson Tennant. He found osmium in the residues from the solution of platinum ores in 1803.

We named our osmium coating system “Tennant20” with the hope that we, like Smithson Tennant, will discover superior technologies and contribute to researchers around the world under our mission to “make a better world with science and technology.”

Power control overview

The Tennant20 uses feedback control to keep the coating current at the set value.

The coating current is measured every 1/10000 second and analyzed by a 32-bit microprocessor. The output of the discharge circuit is adjusted by calculating the coating power to get closer to the set current value using a unique algorithm based on PID control.

This controls the inrush current at the start of discharge, enabling highly reproducible deposition processing.

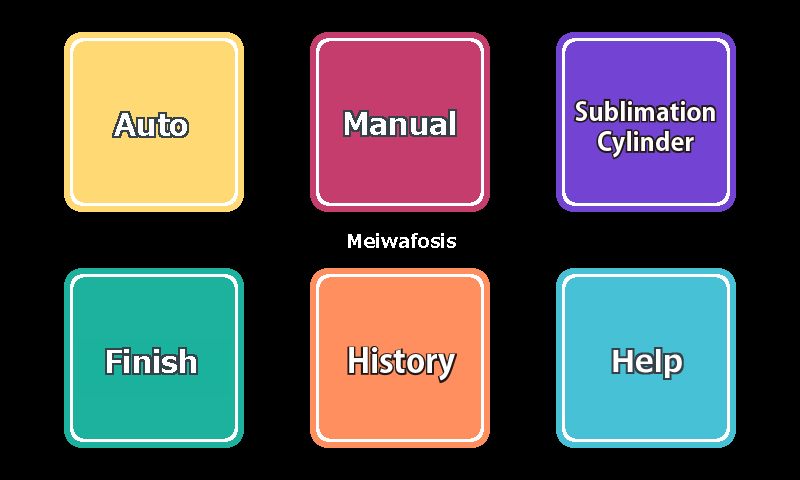

Simple and intuitive operation screen

The operation screen is simple and intuitive. Even a first-timer can operate the device easily.

There are six options on the main screen.

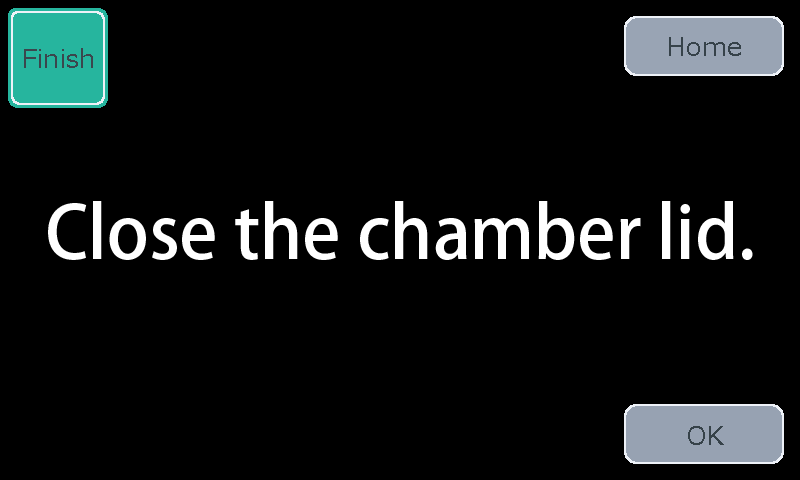

After selecting one, just follow the instructions.

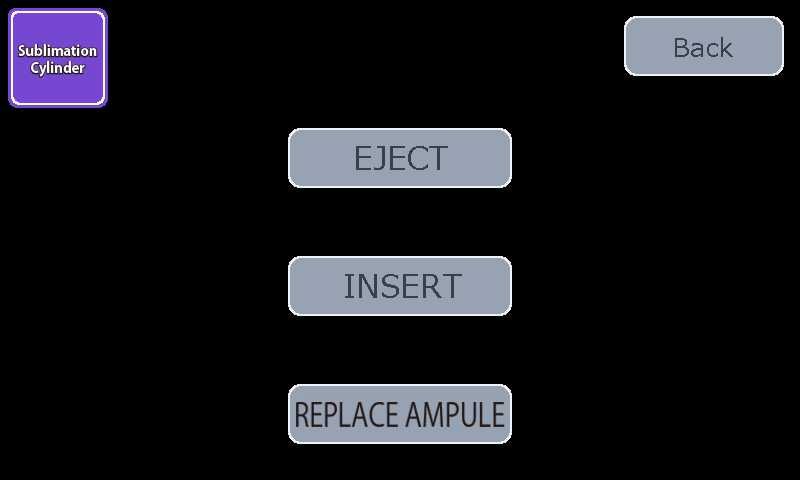

You can eject or insert the sublimation cylinder containing an Os ampule. The instructions are given interactively. Anyone can change the ampule easily.

The Finish mode is for vacuum lock after use. It keeps vacuum drawing in the chamber for storage management.

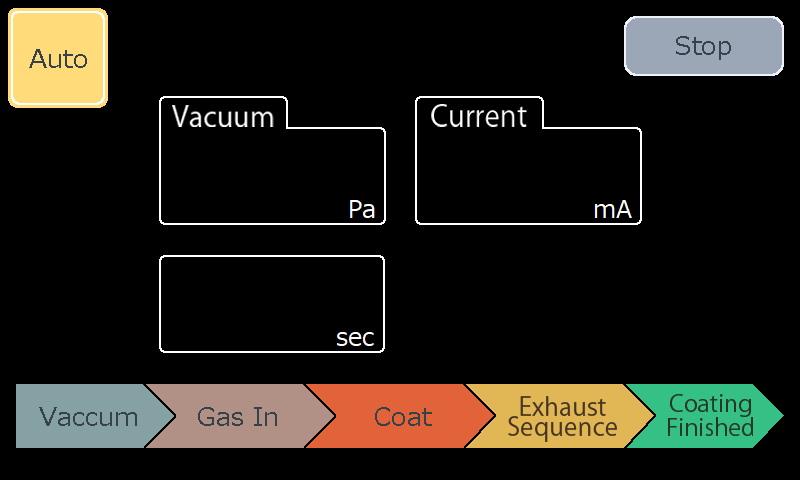

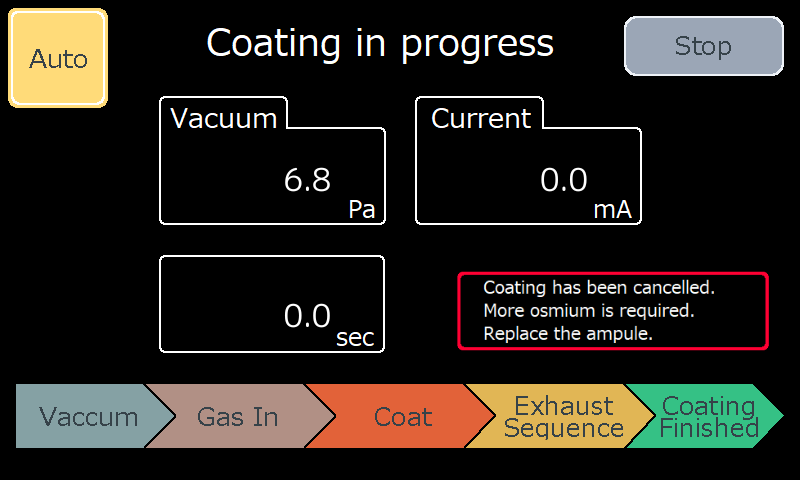

All you have to do is enter a film thickness value. Vacuuming, coating, cumulative coating and exhaust sequence can be done automatically.

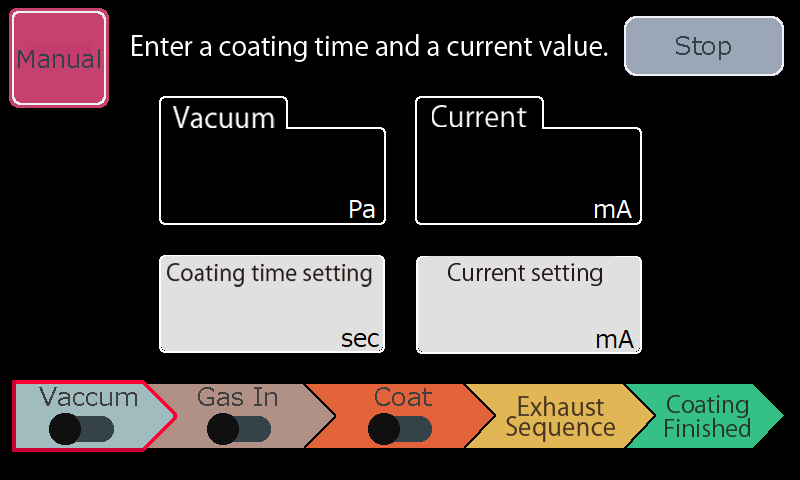

Manual operation option is also available. You can set the timing of gas introduction, the coating time and the current value.

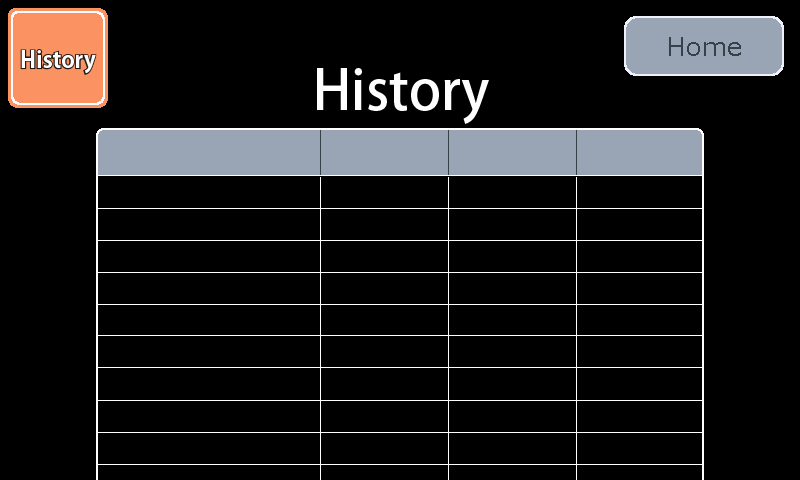

History shows the user, the date, and the conditions. It also records the dates of ejecting/inserting the sublimation cylinder.

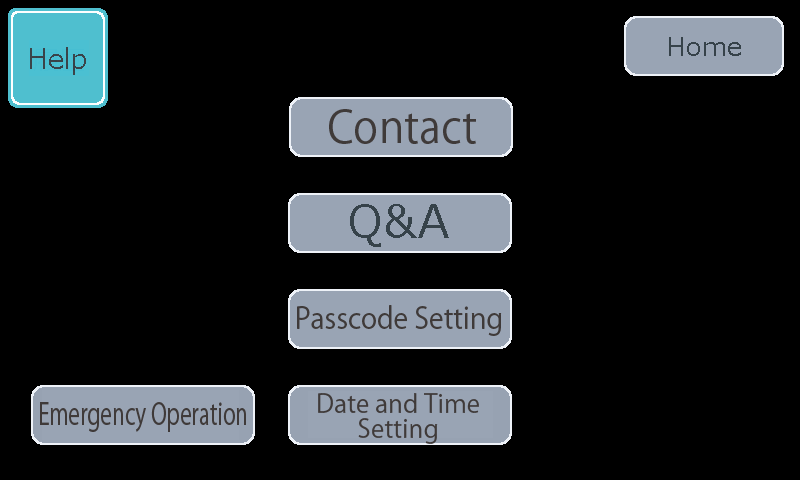

Contact information, Q&A, passcode setting, date and time setting, and emergency procedures are available under Help.

Automatic notification of ampule replacement

A notification appears on the screen when the osmium ampule needs to be replaced. Anyone can easily replace the ampule by following the instructions.

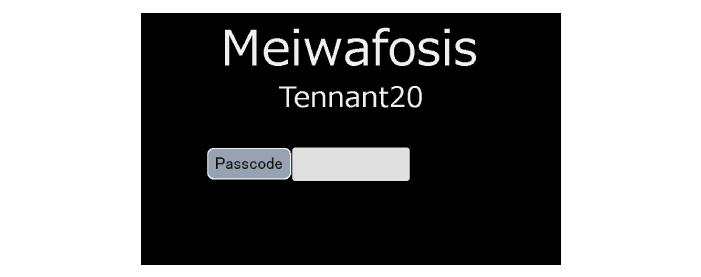

Passcode limits users

A passcode is required for security and management. Only authorized users can operate the Tennant20. By entering your passcode, the operation history will be automatically recorded. The usage status can be viewed in a list without having to make a separate note.

Tennant20 main features

| Each parameter displayed on touch-screen |

| Stable discharge by digital control of coating conditions |

| Vacuum holding function when power is off |

| Auto mode option (only requires film thickness and number of cumulative coats) |

| Smooth opening and closing with chamber handle |

| Passcode for security and management |